About Hess

and the

Hess Pumice Deposit

About the Hess Pumice Company

IT IS CERTAINLY AN ADVANTAGE to have a world-class pumice deposit, but it would mean little if that naturally pure pumice could not be expertly and consistently grade-refined and grade-blended to meet the demands of each industrial process or product component spec.

IT IS CERTAINLY AN ADVANTAGE to have a world-class pumice deposit, but it would mean little if that naturally pure pumice could not be expertly and consistently grade-refined and grade-blended to meet the demands of each industrial process or product component spec.

Pumice is a naturally occurring, incredibly versatile foamed glass stone that is extensively used in a variety of ingenious ways. But the path from mined to refined takes specialized processing facilities backed by an expertise held by a rare few. The Hess Pumice Products company in Malad City Idaho (USA) has been refining pumice for widely-specialized processes and markets for over sixty years.

Hess Pumice began operations in the late fifties crushing and shipping pumice to regional block plants. When the family’s second generation joined the operation—Marvin Hess, a University of Utah-trained engineer—operations moved to a new level. Knowing they possessed a pumice deposit far beyond ordinary, Marvin developed sophisticated crushing and grading processes that allowed Hess to offer a variety of fine-tuned grades for abrasive polishing and shaping applications. Based on the naturally pure quality and consistent results of the pumice Hess was delivering to the performance-critical abrasives markets, Hess Pumice Products expanded into the world-wide marketplace, shipping pumice products into two dozen countries.

A CULTURE OF INNOVATION

Fueled by that success, Hess Pumice continues to innovate, relentlessly exploring possibilities and expanding the uses for our pure white pumice. For example, we developed grinding and capture processes that produce microfine pumice powders—the finest grade (NCS-3) has an average particle size of 3 microns! These safe, non-crystalline powders are used in the paint, coatings, and rubber products industries as functional silica fillers.

Another example of our efforts to develop valuable uses for pumice is our research and subsequent success in helping to reintroduce the construction industry to the performance and endurance boost that natural pozzolans, especially pumice pozzolans, provide to concrete.

Lightweight bonding mortars and stuccos, aggregate for lightweight stone veneers, pozzolanic hydraulic lime (PHL) plasters, soilless grow media, air and liquid filtration media, composting and soil amendments, exfoliating grit—all represent additional uses and processes met by our 70+ pumice grades.

TALK TO AN EXPERT

Yes, we know pumice, but we are also deeply experienced in pumice-related product and process development. We welcome the opportunity to work with innovative companies and individuals looking to develop new processes and pioneer applications that include pumice. We continually invest in our grinding, grading, testing, blending, and packaging processes and equipment. Contact us—let’s discuss the possibilities.

About the Hess Pumice Deposit

PUMICE IS OF NATURAL ORIGIN, a frothy silica glass that has its genesis in volcanism. Deep underground, under immense pressure, water is force-mixed with molten rock. When that water-infused magma escapes to the surface in violent eruption, the trapped water flashes to steam, frothing the rapidly cooling stone. It falls back to earth as pumice.

PUMICE IS OF NATURAL ORIGIN, a frothy silica glass that has its genesis in volcanism. Deep underground, under immense pressure, water is force-mixed with molten rock. When that water-infused magma escapes to the surface in violent eruption, the trapped water flashes to steam, frothing the rapidly cooling stone. It falls back to earth as pumice.

In the particular case of the Hess deposit, our pumice fell onto the surface of an ancient inland sea—a vast lake that once covered parts of present day Utah, Nevada, and Idaho. The Great Salt Lake is all that remains. Through centuries of wave action, the pumice was washed clean, scrubbed of heavy metals and other contaminates to a remarkable purity. Over time, it was layered into a deep deposit on the northern shore of that vast paleolake.

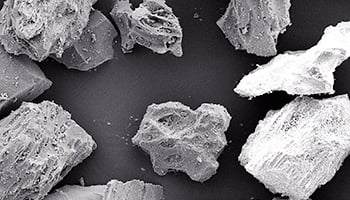

Physically, pumice is a naturally calcined volcanic glass foam consisting of highly vesicular strands permeated with tiny holes. Chemically, pumice is an amorphous aluminum silicate composed primarily of Silicon Dioxide and Aluminum Oxide, with traces of various other oxides.

PUMICE CHARACTERISTICS VARY DEPOSIT TO DEPOSIT

Being of natural origin, all pumice is not the same. Some deposits carry more impurities than others. Some are effectively harder, others softer. Color varies greatly. Other variations are found in the relative tightness of foamed matrix, chemical composition of the volcanic glass, friability, and more.

NOTE The Hess-pumice specific physical and chemical characteristics data is found on the technical data sheets for each Hess pumice grade.

PUMICE ECONOMICS

As per the theme and purpose of this comparative site, the naturally-calcined nature of pumice provides an inherent economical advantage over furnace-calcined pumice-like products. Pumice mine grades are especially cost effective in applications that do not require additional refining to meet exacting specifications.

We have provided links to purchase samples of various grades for various applications on the primary Pumice Verses X page, grouped by potential usage. We invite you to acquire a sample and put it to the test. Contact us for additional information on specific use possibilities. Learn more about pumice and its variety of uses from the websites linked below.